There are several ways of sifting loose materials. One of the best equipment for such purposes is the screening machine. These devices differ not only in increased productivity, but also in high strength. Sieves are one of the main parts of the screen, used for the separation of bulk materials.

There are several main types of this product:

- Steel;

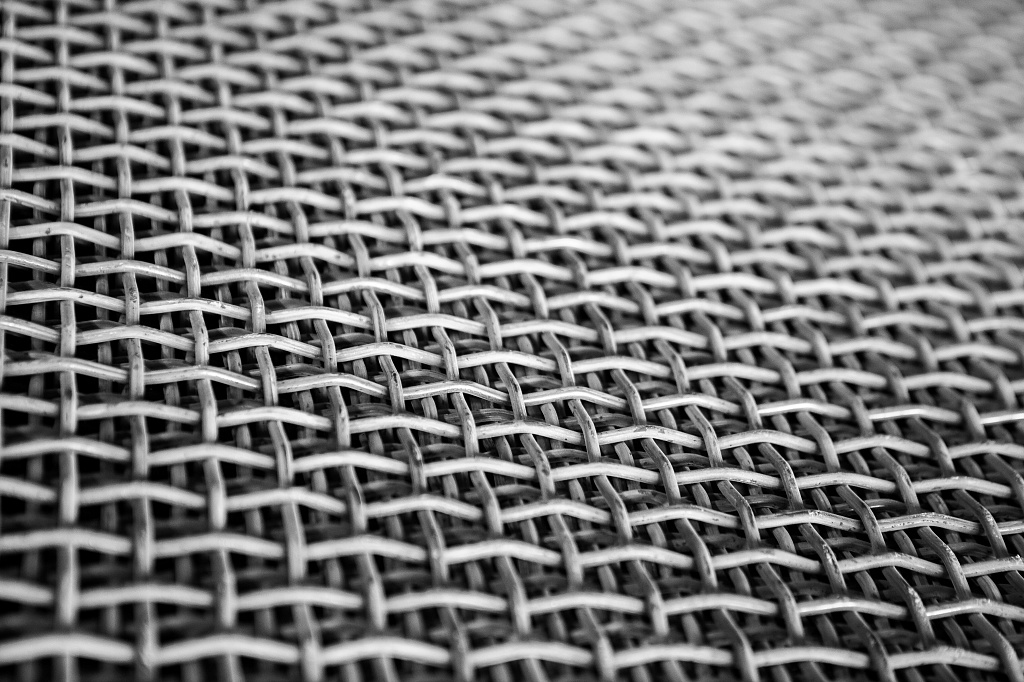

- Woven;

- Stringed;

- Polymer.

The first kind of screen is recommended to be used in those cases when the product requires increased wear resistance, but the weight should be minimal. This type is made of high quality steel. As a rule, they are resistant to mechanical damage, scratches, cracks and dents. Most often, steel screens are used in mining or gold mining industry using materials with high abrasiveness.

The advantage of woven sieves is that they are easy to repair, while they have a low weight. For this type of sieves, a wire is used of various metals: carbon, high-carbon and stainless steel. For example, in contact with materials of high humidity, stainless products that are resistant to corrosion. The most commonly used types of cells in woven models are:

- Rectangular;

- Slotted;

- Square.

Also one of the most used types of sieves are strings. They have more performance than the previous product. In addition, the advantage of string sieves is that it is almost impossible to clog them, and if such a situation occurs, they are cleaned independently. This is due to the fact that their construction does not use interwoven and transverse wires. In this form, the strings are made of stainless steel or spring steel. Such products are recommended for use in the most bulk materials, for example, they are perfect for coal separation.

Sieves, which are made of polymer materials, are inferior in terms of durability to types made of steel. Despite this, such products have a greater reserve of efficiency. For their production, rubber or polyurethane is used. It is worth noting that during the use of the product from the second material, the cells gradually discolor, which causes them to become larger in diameter, which negatively affects the quality of production. The advantage of this type is lightness at a low price, which allows it to be used in small screens.

How to choose a sieve

When choosing it is necessary to take into account such technical characteristics as:

- Product weight;

- The value of the cells;

- Durability;

- Material.

In addition, when acquiring such products, it is necessary to be guided by the type of application of the sieve. Specific types of industry are characterized by their types of sieves.

In conclusion, it is worth noting that it is important not only to pick a high quality sieve, but also care for its maintenance, otherwise it may break down before the due date.

Русский

Русский English

English