Free all over Russia

+7 (800) 550-98-11

Blog

- Home / Blog

Conveyor systems are special equipment, assembled in a certain type of construction, which helps to move, pack, transport cargo, products. With their help, the process of production is automated and accelerated, and the quality of the work performed increases. Applications Such equipment is most often found in such industries: Food production; Mining industry; Machine-building enterprises; Metallurgical industry.

Conveyor mechanisms are widely in demand in various industries. The carrier part of the conveyor is a polymeric or rubberized belt, used as a carrier track. But to ensure a full production cycle and tape performance of traction functions, it should be in the form of a homogenous fabric.

Moving a dimensional cargo with a conveyor belt is the most efficient way of transportation. Among the variety of conveyor devices, the most preferred are the steel cord bands. A metal chord is a cable made of steel (brass thread). It is used as a reinforcing material in the production of conveyor belts.

The technological process of separating bulk materials into classes, depending on the size of their constituent particles (pieces), is called screening. On special equipment - screens - the mechanical separation of the material is carried out using a sieve, through the holes of which pass all the smaller pieces, and larger ones remain on top.

Conveyor rollers are important parts of belt type conveyors. Metal structures are responsible for the movement of the track and giving it a special shape in the form of a trough. The design of the demountable conveyor roller is quite simple: it consists of a cylindrical drum located on the axial shaft, a bearing required for rotating the movable axis of the device, the form, the bearing assembly.

The conveyor (transporter) is a continuous equipment, the purpose of which is to transport various objects and cargo. This mechanism is the main and integral part of any production, it radically facilitated the stage of assembly of complex products, and in fact earlier it required high qualification and experience of workers.

Causes of wearing-out of the conveyor belt during operation Problems with the belt for the conveyor can arise as a result of non-compliance with the rules of operation of the product. Below are the main reasons for the premature failure of conveyor belts.

Ways to increase the service life of the conveyor belt The main task in the operation of the conveyor is to increase the operating period of the moving fabric. This can be achieved with the help of rubberizing (lining) drums. As a result of giving the drum a barrel-like shape, the load-bearing unit is protected from premature wear.

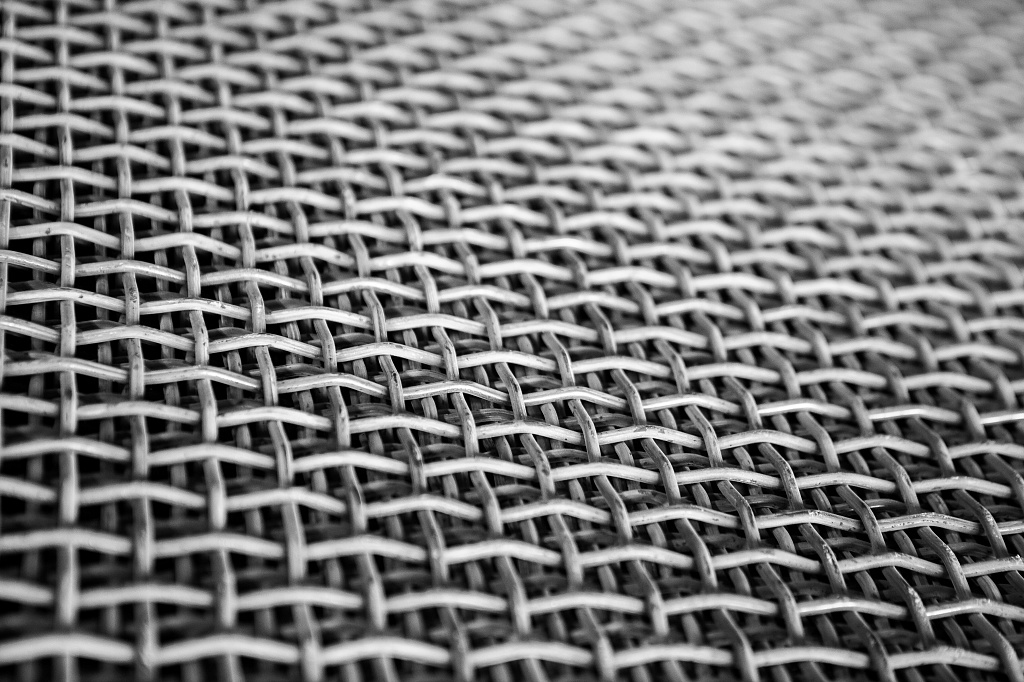

There are several ways of sifting loose materials. One of the best equipment for such purposes is the screening machine. These devices differ not only in increased productivity, but also in high strength. Sieves are one of the main parts of the screen, used for the separation of bulk materials. There are several main types of this product: Steel; Woven; Stringed; Polymer.

Screening is the process of separating classes of a certain size from the total mass of the initial material, carried out by using screening surfaces with the required hole parameters. The separation of the initial material into the upper and lower classes occurs by moving the rotating, moving, partially moving or fixed screens along the screen.

Screening is the technological process of separating bulk raw materials according to particle sizes on screens that consist of one or more vibrating sieves. If the process is mechanized, the screens act as machines or apparatus. Screening can differ according to technological use: Auxiliary, in the process of which the fine fractions of the raw material are separated; Control (verification), separation of fine fractions of crushed material;

Latest

-

17.07.2018Conveyor systems

17.07.2018Conveyor systems -

17.07.2018Equipment for docking conveyor belts

17.07.2018Equipment for docking conveyor belts

© 2012 - 2022 «Eurosito» Company

info@euro-sito.ru

Promotion and development aggo.ru

Promotion and development aggo.ru

Русский

Русский English

English