Screening is the process of separating classes of a certain size from the total mass of the initial material, carried out by using screening surfaces with the required hole parameters.

The separation of the initial material into the upper and lower classes occurs by moving the rotating, moving, partially moving or fixed screens along the screen. In the process of screening, particles with a smaller diameter than the diameter of the screen hole enter the sub-grid product. The material, the size of which exceeds the diameter of the screen, remains on the surface of the screen and forms the upper superficial product.

The effectiveness of screening depends on such indicators:

- Time of sieving and uniformity of the material supply to work;

- Dimensions and design of the screening surface;

- Angle of inclination, frequency and trajectory of oscillation of screens;

- Granulometric, real composition and geometric shape of grains;

- Humidity of the starting product.

Scope of application

Depending on the technological purpose, the sorting of bulk materials is carried out for the purpose of:

1. Preliminary separation of small classes from a large fraction for their subsequent separate processing;

2. Dehydration and desliming of the initial mixture or separation of the suspension from the conditioned product;

3. Verification and control of the size of the resulting material, which must meet the requirements of the standards for size.

These directions predetermine the scope of sifting screens, which have found wide application not only in the mining and coal industry or agro-industrial complex. The need to separate the material by its size arises in non-ferrous, ferrous metallurgy, construction, food, chemical and machine-building industries.

For the production of building mixtures, equipping quarries, mines, mines, concentrating mills, various sieves with specific cell parameters are used.

Design varieties of sieves for screens

The correct selection of the screening surface makes it possible to increase the efficiency of processing the starting material. Certain structural features with different sizes of holes, material and method of fastening make it possible to adjust the production process in accordance with the technological scheme of processing the product. In connection with this, the following types of sieves for screening can be proposed:

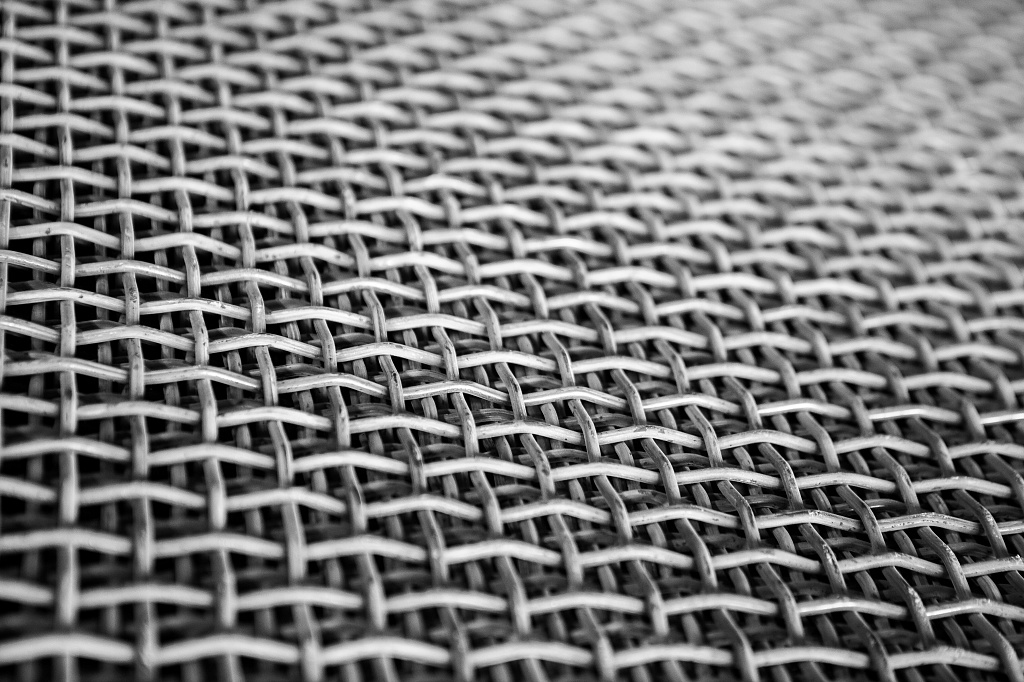

- Woven screens for mobile and stationary screens are made of high-quality wire or a rod with a high-alloy composition used to separate loose materials of building materials, coal, mineral fertilizers, seeds;

- Welded screens meeting the necessary requirements are capable of carrying significant loads and are used for filtration, dehydration, water treatment and water purification in various spheres of economic activity;

- Perforated from stainless steel made of wear-resistant sheet steel, so suitable for processing granites, stones, coal, rock and other materials of mining, metallurgical and cement industries;

- Polyurethane screens are an alternative to rubber and metal products, installed in the sieving stage to filter ores, sand, coke, slag, limestone and other rocks;

- Finger-shaped (grate) with a cascade arrangement allow to cope with sifting of clayed coarse-lump materials, dolomite and limestone;

- Harp-like or self-cleaning surfaces made of wear-resistant spring wire are effective for separating clay rocks or removing silt particles;

- Strings of high-quality steel grades are distinguished by a high level of screening in dry sorting of construction materials and raw materials of the coal mining industry;

- Slotted or sintered gratings are used for classification, separation or grinding, and grids in the form of cylinders help to filter gaseous and liquid media.

The use of high-quality materials and modern technologies makes it possible to create reliable equipment with a long service life.

Русский

Русский English

English